We all know that aluminum electrical wiring in homes can lead to fires. Allow me to share a recent experience:

I got a call from a Realtor who said her buyers were excited about this 1973 home. However, the home inspector discovered aluminum wiring in the electrical box. The homeowner reassured them, saying, “It’s okay, Uncle Dave was here two weeks ago and pigtailed all the plugs and switches.” Concerned, the Realtor asked me to inspect the aluminum electrical wiring system to ensure its safety. The importance of properly installing electrical wiring cannot be overstated.

Upon arriving at the house, my first action was to check the electrical panel to assess the extent of the aluminum wiring. Opening the cover, I found that half of the electrical wiring incoming was aluminum. The other half was copper, showcasing the diverse materials used in homes.

This is a common situation in homes with wiring from the early ’70s when aluminum was often used. Due to budget constraints, new home builders finished the main floor wiring of a bungalow with aluminum, leaving the basement unfinished. When subsequent homeowners later had the means to work on the basement, they chose copper wiring instead.

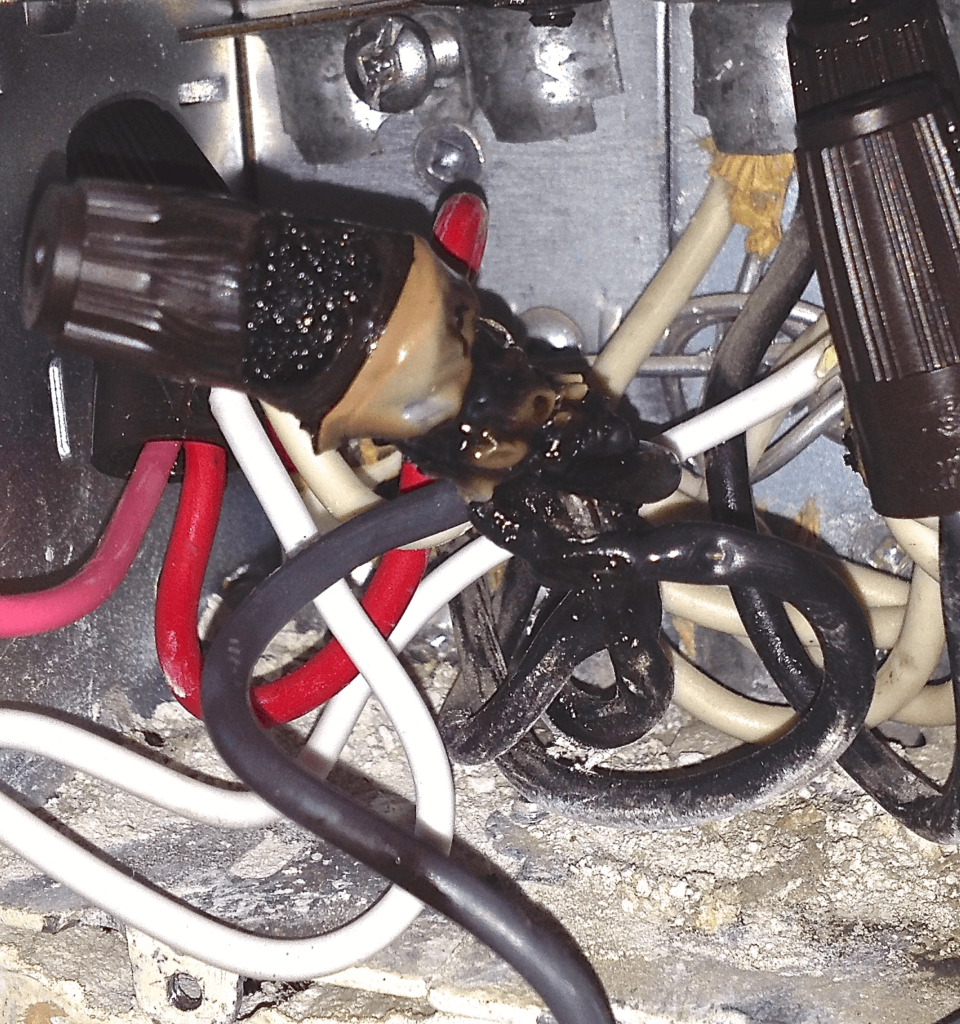

Inspecting panels with aluminum wiring often reveals issues like overheated conductors and melted breakers. These are common problems we frequently encounter with faulty installations related to aluminum wiring in homes.

I inspected the main floor by opening a few wall plugs and switches to examine Uncle Dave’s work. Proper electrical wiring pigtailing involves four crucial steps. First, an anti-oxidizing paste must be applied to coat exposed aluminum and copper conductors, which prevents oxidation when the metals come into contact. Uncle Dave had successfully completed this part.

The second aspect is checking if the “twist-on” wire connectors are appropriately rated for aluminum/copper connections. Uncle Dave used connectors suitable for this application.

Thirdly, the plug or switch needs to be rated for copper since the wires to the device are now copper. Lastly, the wires must be twisted together in a clockwise rotation before installing the wire connector. Unfortunately, this is where Uncle Dave fell short in installing electrical wiring correctly.

While electricians know to twist wires together first, non-electricians may lack this critical knowledge when dealing with aluminum electrical wiring practices. In this case, when attempting to install the connector, one conductor was pushed down inside the connector instead of twisting around the other, leading to arcing and potential fire hazards. Such risks are often linked to improper practices of wiring.

By the back door, I discovered a 3-gang switch box that emitted an unusual odor. Removing the cover, I found that just two weeks after Uncle Dave’s work, the insulation on the wiring had melted. This incident emphasizes the importance of obtaining an electrical permit and having the project inspected by an approved professional. An inspector would have identified the lack of twisting in the wires. This would have prompted a failed inspection and required Uncle Dave to perform a proper installation.

If you have concerns about the electrical wiring work in your client’s home, we are here to help. Contact us for a no-obligation quote at (780) 705-3696.

Featured photo: shutterstock.com